HOTMELT MOULDING

Highly modular processing machines for coating and potting

With hotmelt moulding processing machines, we enable users to cast parts with lower injection pressure and lower temperatures than in plastic injection moulding.

Our WERNER WIRTH processing machines for overmoulding and casting are designed to be modular, allowing for easy changes, additions, and expansions as needed. The modularity enables a switch from tank technology to extruders, from horizontal to vertical filling. Thus, the machines offer a seamless adaptation to changing production needs.

As a one-stop solution partner for component protection, we also provide you with the appropriate materials, hotmelt tools, and contract potting. WERNER WIRTH really does give you everything from a single source – even ready made on request.

Hotmelt moulding platforms by WERNER WIRTH – the perfect solution for every challenge

- From entry-level to high-performance large-scale production models

- Individual configuration

- Maximum occupational safety

- modular & adaptable, can be extended at any time

- Sound advice included

Modular processing machines for hotmelt moulding

PROTECTIONFrom low-cost entry model through to complex mass production machinery

The hotmelt moulding range by WERNER WIRTH extends from handguns for small batches through to complex injection moulding machines for inlay parts, resulting in the individually ideal solution for every customer requirement. Our convincing advice is also promptly provided.

Work with us to plan your new, bespoke hotmelt moulding platform and discover all the many possibilities. Whether individual workstations for small series or mass production modules that fit in smoothly with your production line, we are used to thinking in terms of the bigger picture on a large scale, so not even the smallest detail is forgotten while still saving few minutes here and there – for even more efficient production workflows.

Hotmelt moulding machines

Hotmelt moulding and potting platforms at a glance

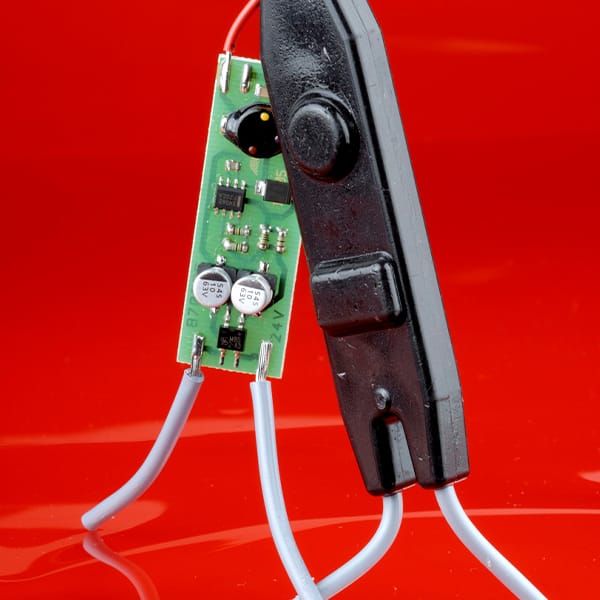

Take a look at our large selection of ergonomic hotmelt moulding machines that are suitable for potting cables, connectors, coils and sensors and even for whole electronics modules. Which platform is best suited to your individual requirements?

With the TM 2000 series, we offer electronically controlled hand applicators for processing hotmelt polyamides. The TM 2000E, which is also available for rental, addresses tasks in laboratory and experimental operations. The TM 2000Z system is designed for use in small-series production. With a mounting stand and time control, it ensures reproducible results.

The TM 2000 series devices can be quickly filled, boasting high melting performance and optimal time control. The encapsulation takes place in low-pressure injection molding within a pressure range of 1.5 to 5 bar.

The temperature is continuously adjustable with an accuracy of ±1°C, ensuring low thermal stress on molded parts. The use of aluminum tools results in low tool costs.

The low-cost entry level model for hotmelt processing

The TM 2200 moulding station is our low-cost entry-level machine for hotmelt moulding. The standard version comes as a modular system with tank unit TM 1004 and moulding head TM 1010.

Product description TM 2200:

The mould holder is big enough to take common standard mould sizes with horizontal injection. TM 2200 with its vertically moving cylinder can be adjusted to many different mould heights. The standard height adjustment for moulding head TM 1010 permits the use of different separation levels.

The manual sliding table with the lower mould half comes out towards the operator, making it easy to insert the parts. Once the lower mould half has moved back in again, the machine is fully encapsulated once more, offering maximum safety.

The machine is designed to be used by one operator. The operator starts the purely pneumatic cycle with the practical one-hand control. TM 2200 with its clamping force of up to 700 kg is the ideal solution for processing small and medium-sized series.

Thanks to the unique versatility of WERNER WIRTH’s moulding platforms, TM 2200 can also be fed by a range of different material preparation systems, from tank unit to extruder.

Fully modular hotmelt processing machine for practically every application

The TM 2300 moulding station with its consistently modular structure is the most flexible solution for producing your hotmelt application.

Product description TM 2300:

The available mould holders are compatible with all common standard mould concepts, right through to holders for hot-runner moulds. Cooling or tempering the specific potting material depends on the process requirements and takes place directly in the mould holder, thus making it easier to change the mould while also eliminating the need for loose hoses and hose connections.

The single or multiple gate can be vertical or horizontal, fed by the material conditioning systems needed by the specific materials being processed. The standard clamping force is 1400 kg and can be extended with different cylinder sizes or by using additional mould closure systems. The manual lower mould comes towards the operator, thus offering unhindered access to insert the parts for processing. The variable holder level of the upper mould reduces the closing stroke for the shortest possible closing times.

The machine is designed to be used by one operator. The optional use of a switchbox makes it possible to operate two TM 2300 platforms with just one material feed. This results in the greatest possible production capacity for one operator with ideal cost effectiveness. Compliance with level D of the Machine Safety Directive offers maximum occupational safety going way beyond the minimum requirements.

Thanks to its unique flexibility, the TM 2300 moulding platform is the ideal solution for all applications from the small series platform with tank unit through to the extruder-fed double moulding station or an inline solution for mass production.

Highly flexible processing machine with manual closure for small series

In the low-cost standard version with TM 1004 tank unit, the TM2500-4 moulding station is the ideal entry-level system for hotmelt processing.

Product description TM 2500-4:

The open design of the mould holder offers sufficient scope particularly when coating cable systems or partially coating foils or more complex components. Thanks to the vertical adjustment mechanism, the TM 2500-4 can be set up for many different mould heights, thus offering a highly variable mould holder solution for the gate in the separation level. The pneumatic lower mould half comes towards the operator, thus offering maximum occupational safety thanks to the combined mechanical and pneumatic mould closure with clamping force of up to 1500 kg. The practical one-hand control closes the mould to an opening of just 5 mm. Pressing the start button on the lever triggers pneumatic closure and starts the injection moulding process.

The machine is designed to be used by one operator. The optional use of a switchbox makes it possible to operate two TM 2500-4 platforms with just one material feed, resulting in the greatest possible production capacity for one operator with ideal cost effectiveness.

Thanks to its unique versatility, the TM 2500-4 is the ideal solution for all applications from the small series platform with tank unit through to the extruder-fed double moulding station for medium-sized series.

Twice the output with just one operator

The units in the modular moulding platform TM 2500-TWIN communicate with each other and are ideally designed for optimum feed to both platforms with just one material feed point.

Product description TM 2500- TWIN:

In the standard version with TM 1004 tank unit, the TM 2500-TWIN moulding station is the ideal entry-level system for hotmelt processing. The open design of the mould holder offers sufficient scope when coating cable systems, partially coating foils or more complex components.

Thanks to the vertical adjustment mechanism, the TM 2500-TWIN can be set up for many different mould heights, thus offering a highly variable mould holder solution with different heights in the separation level.

The pneumatic lower mould halves come towards the operator for convenient inserting and removing of the parts. The practical mechanical and pneumatic one-hand control offers maximum occupational safety for mould closure with clamping force of 1500 kg.

Highly flexible low pressure moulding machine with semi-automatic mould closure

As a low-cost standard version, the TM 2500-5 moulding station with tank unit TM 1004 is the ideal entry level for low pressure moulding.

Product description TM 2500-5:

The open design of the mould holder offers sufficient scope particularly when coating cable systems or partially coating foils or more complex components.

Thanks to the vertical adjustment mechanism, the TM 2500-5 can be set up for many different mould heights, thus offering a highly variable mould holder solution for the gate in the separation level.

The practical one-hand control closes the mould to an opening of just 5 mm. Pressing the start button on the lever triggers pneumatic closure and starts the injection moulding process.

The machine is designed to be used by one operator. The optional use of a switchbox makes it possible to operate two TM 2500-5 platforms with just one material supply. This results in the greatest possible production capacity for one operator with ideal cost effectiveness.

Thanks to its unique versatility, the TM 2500-5 moulding platform is the ideal solution for all applications from the small series platform with tank unit through to the extruder-fed double moulding station for medium-sized series.

Classic moulding platform with automatic sliding table and maximum occupational safety

The TM 4500 moulding station is designed specially for medium-sized series in low pressure moulding technology. The compact shape permits productive manufacturing of small to medium-sized coating procedures of inserted parts, e.g. for sensors, harness assembly or electronic modules.

Product description TM 4500:

TM 4500 stands out with a three-part concept. Full tooling consists of one upper mould and two identical lower moulds. The gate consists of one or two injection valves positioned horizontally to the rear in the mould separation level.

The lower mould halves are changed on an automatic sliding table under the upper mould. A Plexiglas safeguard protects the operator while the procedure takes place. Mould closure is pneumatic, thus offering maximum operator safety with convenient two-hand control up to clamping force of 1400 kg.

The machine is designed to be used by one operator. The optional use of a switchbox makes it possible to operate two TM 4500 platforms with just one material feed. This results in the greatest possible production capacity for one operator with ideal cost effectiveness.

Thanks to its unique versatility, the TM 4500 moulding platform is the ideal solution for all applications from the series platform with tank unit through to the extruder-fed double moulding station for larger series.

Powerful hotmelt processing machine for large-batch operation with maximum clamping force of 3000 kg

The low pressure moulding machine TM 6500 is designed specially for coating inserted parts in mass production. The ergonomic structure and flexible configuration possibilities allow proliferous production of two identical or also different coatings of inserted parts, e.g. for sensors, harness assembly or electronic modules.

Product description TM 6500:

TM 6500 stands out with two mould holders that can be controlled independently of each other. The possible mould dimensions offer space even for relatively large cavities, or multiple cavities for greater efficiency, depending on the size of the moulded element.

Sprue is provided by one or two injection valves horizontally from the rear in the mould separation level. The lower mould halves come towards the operator and move on an automatic sliding table under the upper mould. A Plexiglas safeguard protects the operator while the procedure takes place. Mould closure is pneumatic or hydraulic, thus offering maximum operator safety with convenient two-hand control up to clamping force of 3000 kg.

The machine is designed to be used by one operator. The optional use of a switchbox makes it possible to operate two TM6500 platforms with just one material feed, resulting in the greatest possible production capacity for one operator with ideal cost effectiveness.

Thanks to its unique versatility, the TM 6500 injection moulding machine is the ideal solution for all applications from the series platform with tank unit through to the extruder-fed double moulding station for larger series.

Versatile hotmelt moulding platform with the greatest possible flexibility for the highest demands and superb performance with clamping force of up to 6000 kg

The TM 6800 injection moulding machine is designed specially for coating inserted parts in mass production. The ergonomic structure and flexible configuration possibilities allow proliferous production of many different coatings of inserted parts, e.g. for sensors, harness assembly or electronic modules.

Product description TM 6800:

TM 6800 is designed for processing thermoplastic materials with max. 50 bar in the temperature range up to 250°C. The machine stands out with maximum possible flexibility in the mould holder. It can be fitted with a horizontal sliding table or a version that brings the lower forms to the operator. It can also be used in inline processes with the moulds fitted automatically by a robot. The possible mould dimensions offer space even for relatively large cavities, or multiple cavities for greater efficiency, depending on the size of the moulded element. Sprue is provided by one or several injection valves horizontally from the rear in the mould separation level. Vertical sprue-less moulding is also possible directly into the upper mould.

A Plexiglas safeguard protects the operator while injection moulding takes place. Mould closure is hydraulic and offers maximum operator safety with convenient two-hand control up to clamping force of 6000 kg. Injection moulding machine TM 6800 with its unique versatility is the ideal solution for processing many different thermoplastic materials, from polyamide hotmelt through to standard TPU.

The TM 8000 represents a type of system that can be individually tailored to customer projects. The tool holder is optimised for an ideal production process. It can be configured either as a sliding or rotary indexing table, or as an inline solution. The tool sizes can be individually adjusted to the product and offer maximum flexibility in width, height, and depth.

The tool dimensions provide ample space for relatively large cavities or allow for efficiency improvements through multiple cavities. The cavities can be filled via either cold or hot runner systems. The operation of a TM 8000 can be done either by an operator or fully automatically – from loading to unloading. The control options allow for complete monitoring of the processes before, during, and after casting.

Fusing systems

Tank units, extruders and bag smelters by WERNER WIRTH

We are your partner who always knows how to do thermoplastics. Cheese is the best way to explain this technology to non-experts. But you can be sure we don’t make cheese! WERNER WIRTH offers accumulated know-how for stable viscosity conditions in tank units, difficult shearing forces in the extruder and guaranteed air exclusion in the bag smelter.

WERNER WIRTH is guaranteed to find the right recipe and perfect technology also for your requirements.

WERNER WIRTH’s tank systems are specially designed for processing low-viscosity thermoplastic materials at processing temperatures of maximum 250 °C.

This is the entry-level solution in hotmelt moulding technology. This technology processes granulate materials. The TM 1000 series can be used with all our moulding platforms. Various features are available depending on the particular unit type, including level sensor, weekly timer or temperature reduction.

Hotmelt materials are processed in many different industrial applications. Tank systems are responsible for preparing, storing and conveying the material, from simple dispensing of hotmelt adhesives through to the shaping finish in low-pressure hotmelt moulding.

Product description TM 1004 – TM 1206:

The units are used in WERNER WIRTH hotmelt moulding machines, in complex inline production lines or in semi-manual standalone operation. The structure is optimised to avoid cracking. All units have an adjustable bypass. Individual tank and pump sizes make it possible to configure the units to the individual needs in each specific case.

In conjunction with our innovative valve technology and top quality hose packages, our tank systems are a low-cost possibility for melting hotmelt materials and feeding them to the application in line with the specific process. The systems are made in Germany according to the quality and safety standards valid here. Please do not hesitate to use the WERNER WIRTH on-site service and our hotline.

Extruders in hotmelt technology bring advantages that other tank systems simply cannot offer.

Convenient and reliable: designed for processing a wide range of granulate materials, even for potting or injection moulding materials that are coloured or have higher viscosity. Extruders in the TM1500 series can be integrated in all our platforms. Their useful features include touch-panel control, inverter-controlled drive and a melting rate that is geared to material demand, among others.

In principle, extruder technology can be used not just for processing hotmelt materials. Thanks to the basic technical structure and design of the screw technology, extruders are also capable of processing a wide range of other different materials. Depending on the specific material specifications, extruders can also process polyester, EVAs, polyolefins/polyalkenes and polyamide.

Product description TM 1500:

The technology is developing all the time with an ever growing range of possible applications. At the same time, the requirements are constantly increasing when it comes to the specification of the parts being used. This trend is particularly significant for the physical and chemical load faced by component protection. Whether this refers to the automotive sector or electronics, communication technology, the medical industry or white goods: chemical substances and mechanical loads together with very high thermal stress and vibrations are typical problems that demand active module protection.

Flexibility is our trump card for processing hotmelt materials in low pressure moulding technology. Manufacturers of electrical and electronic modules expect component protection systems that offer rapid, flexible solutions at constantly high quality. The provision of top quality materials is just as important as the specific rating of corresponding moulds and processing systems.

The machine is used to melt, eject and apply reactive and other melt adhesives that are sensitive to temperature.

The bag melter TM 1403 is required when processing high temperature-resistant reactive moulding polyamides in the PAR product group. It can be fitted to all of our moulding machines. The material is melted by a controlled hot plate under an air seal and fed into the mould, and refilled by simply replacing the empty bag with a new one.

A hydraulic plunger presses the adhesive against the melding plate. The same mechanism conveys the adhesive directly in the heated hose to the application head. The melted substance is brought to temperature in a mainly incremental process and protected from moisture, air and dust all the time. Only the required quantity of adhesive is melted. The rest remains cool and unused (“melt on demand”).

Product description TM 1403:

- Melting, feed and application directly from the bag

- Controlled flow of adhesive: the adhesive melted first is applied first

- Absolutely gentle handling of melt adhesives (especially reactive melt adhesive)

- Fully variable adjustment of supply pressure (up to 60 bar)

- Lowest possible thermal load on the adhesive thanks to incremental heating

- Hermetically sealed system: no need for drying air or nitrogen; the hotmelt material has no contact with the surroundings (moist air etc.) at any point in time

- Compact, mobile unit for small and medium-sized application volumes

- Practically no cleaning and maintenance required, even when in use for several years

- Unsurpassed quality and performance even under adverse operating conditions.

Hotmelt moulds

Every piece an example of the very best engineering.

In all modesty, we like to compare this division with clock makers or car manufacturers. After all, this is where experienced mould makers produce almost exclusively unique specimens in unconditional quality. We even don’t mind if our mould makers themselves are rough-and-ready types, as long as there are absolutely no rough edges at all in even our simplest aluminium mould. After all, the sophisticated series mould has to run without a hitch in the end.

At WERNER WIRTH, we like to begin with the specimen mould in the development stage. After hundreds of successful projects, we offer comprehensive know-how right through to highly complex moulds with slides and ejection systems, different sprue techniques or sprue-less hot runner systems. And, of course, in reproducible quality at all times.

We offer solutions for individual challenges – from a single source

Plan your new, customised hotmelt potting platform with us and discover the many possibilities. Be it a single workstation for small series or a large-series module that fits seamlessly into your production line: We are used to thinking about the big picture in a holistic way, taking into account even the smallest detail, and squeezing a few minutes out of somewhere – for even more efficient production runs.

Building on almost 50 years of experience, our expertise in the field of electronics is multi-disciplinary know-how, individual planning, comprehensive advice – and, if you wish, we can offer all of this from one source. In other words, in addition to the processing machines, melting systems, cooling units and temperature control units, we can also provide perfectly suitable materials, design and build highly complex moulds ourselves, and supply the valve technology and all the accessories. you profit from our extensive know-how in every case.

And if we don’t have something, we can make it to customer specifications. By the way, we are also happy to manufacture any number of pieces for you.

Briefly explained: Hotmelt Moulding

We’re at your service

Do you have any questions about Hotmelt Moulding, or would you like to exchange ideas with us about reactive casting without any obligation? We are happy to be your contact person.

Let’s talk so that we can support you in your project with our solutions.

Feel free to call me directly: +49 40 75 24 9114

Yours sincerely, Bernd Conrad