HARNESS ASSEMBLY

WERNER WIRTH assembles your harnesses

Scarcely any other service has so many components and techniques as professional harness assembly for electronic applications: soldering, crimping and resistance welding, single wires, connection leads, complete cable harnesses.

But no matter how specific your requirements may be, we offer you the following advantages:

- Expertise: Built up over nearly 40 years, our know-how in cable assembly is excellent. Since 1984, we have been delivering customized solutions.

- Availability and Cost Efficiency: We assemble cables in own factories in Europe, from Belgern/Saxony, Hamburg to Klaipėda/Lithuania, so twe can guarantee economical production.

- Customer-oriented: Your project, your requirements. We listen, develop solutions and implement them according to your wishes. Our expertise results in a product that is ready for series production.

- Quality and reliability: We ensure the quality of your product and our work through regular intermediate and final tests within our workflows. The following tests are standard for us: pull-off tests, crimp height measurements, crimp force monitoring, length tests, dimensional tests and/or micrographs. Customer-specific special tests are also possible. In addition, we are DIN EN ISO 9001:2015 and DIN EN ISO 14001:2015 certified as a company.

- Resource planning: If you are still at the beginning of your production and/or do not want to set up your own harness assembly yet, then use our service and save time by accessing our expertise.

- UL certification: We are UL certified and can manufacture accordingly for the North American market.

- We offer more: In addition to pure harness assembly, we also offer the option of developing customized connector solutions for you. Regardless of how large the installation space is, we will work out the right solution for you from the concept phase to the finished series product. This means: We offer you support at any time, no matter at which point of the project phase you are.

Harness Assembly: as a service on your behalf

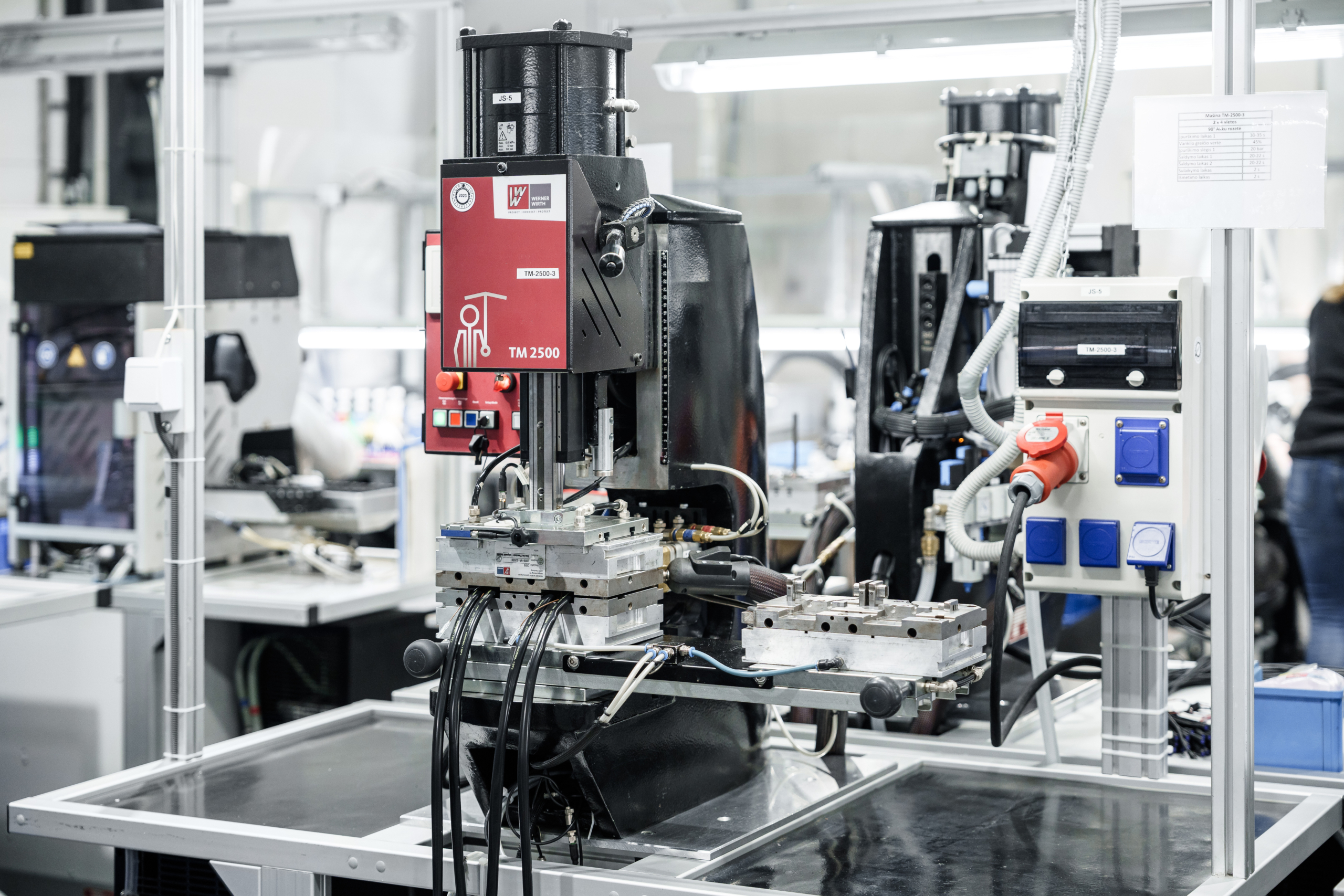

PRODUCTIONAll techniques plus individual manufacturing

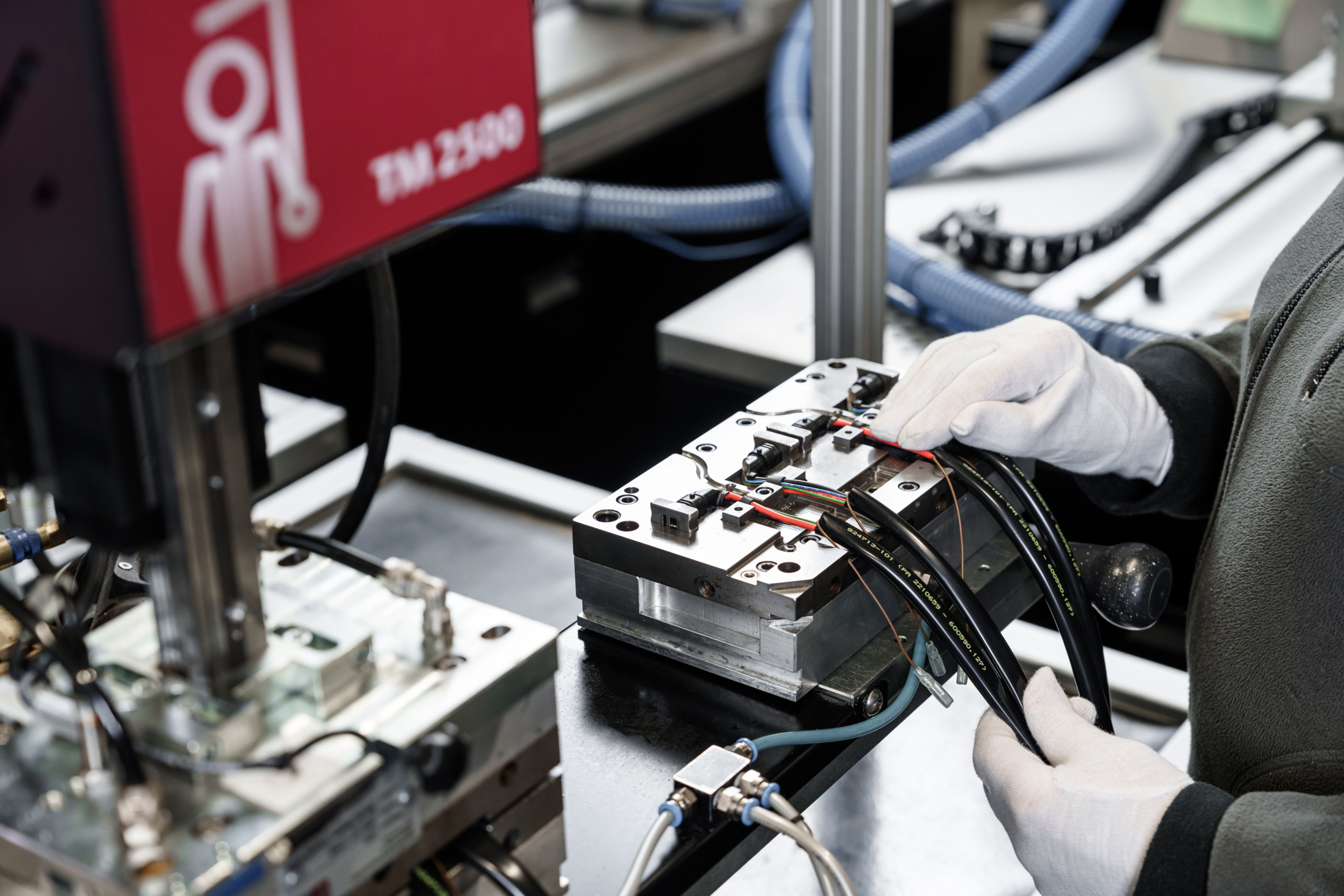

Harness assembly is one of our core fields of expertise. As well as processing standard crimp contacts, we also have a special department for tooling. And so we will find the ideal processing solutions for even the most exotic formats and make them up precisely to your specifications.

We possess comprehensive expertise in tools and techniques, ensuring the right processing solution for every contact and manufacturing precisely according to your specifications. Our products are ready for connection and adhere to all IPC standards, such as IPC/WHMA-A-620 (Requirements and Acceptance for Cable and Wire Harness Assemblies) or IPC-A-610 (Acceptability of Electronic Assemblies), making them ready for integration into your applications.

Thanks to our holistic experience and state-of-the-art Hotmelt Moulding technology, we can seamlessly integrate various electronic components into complex cable systems and provide robust protection with process reliability.

Individual harness assembly

We offer all common harness assembly options to meet your specific requirements.

Crimping is the process of creating a solid mechanical and electrically conductive connection between two components through plastic deformation. We offer this fully automatic, semi-automatic or manual for all types of cables.

Soldering is a part of cable assembly. As a thermal process, soldering enables a permanent connection of cables/materials and is often used when conductivity is is required. The solder melts at relatively low temperatures and forms a solid connection between the metal parts when it cools.

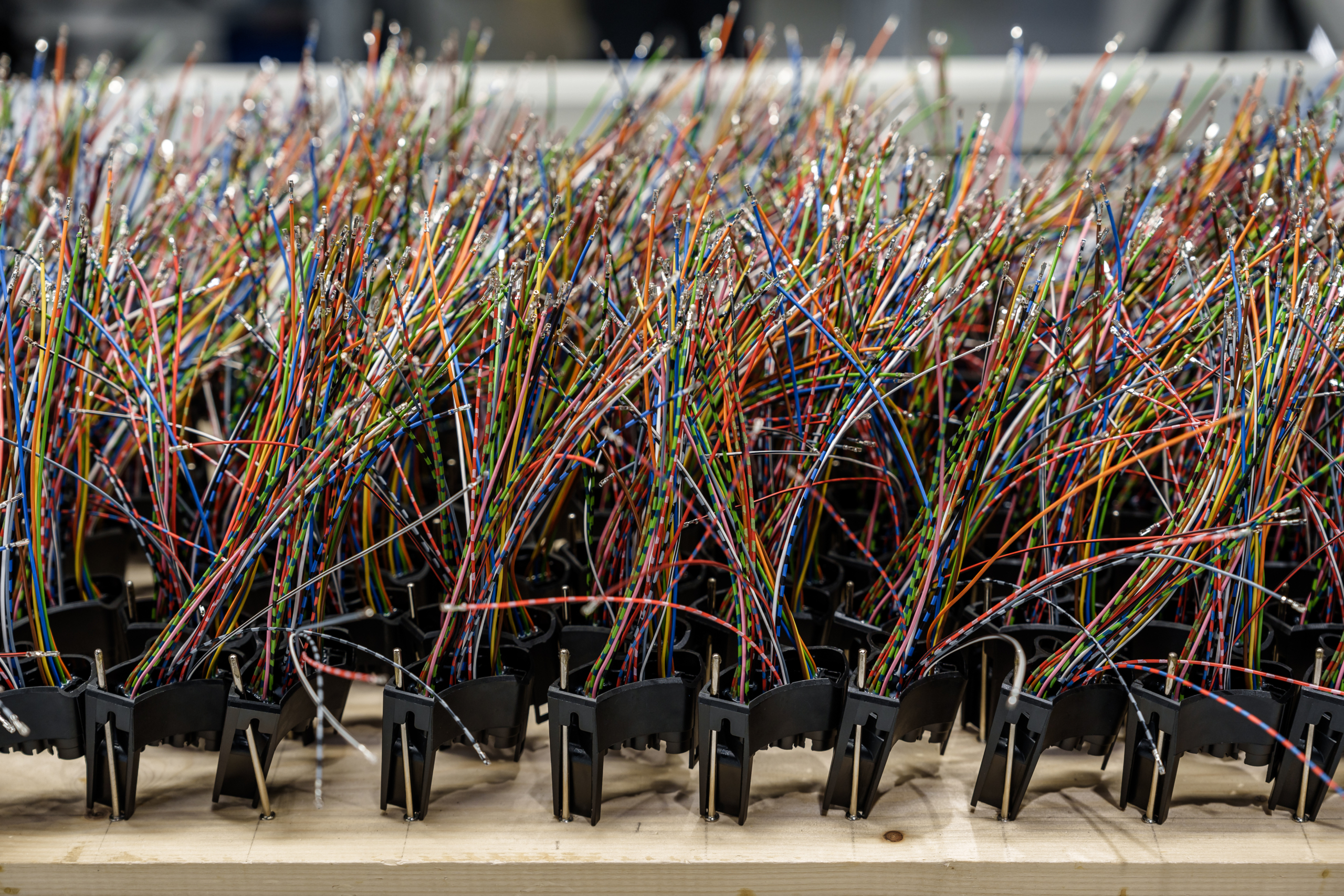

We print, crimp, cut, insulate, contact, twist and/or tin single Wires. Depending on your requirements, we also attach individual banderoles or shrink cable ends, for example.

Cable harness production is part of our solutions in the field of cable assembly and is tailored to individual customer requirements. We are pleased to support you in the development process, handle prototype construction, or produce existing samples. We test the quality of the cable harnesses we build before they are delivered.

Cutting to length enables a precise and millimeter-accurate assembly of cables and can be done semi- or fully automated. After cutting to length the cables, the next step is usually the stripping process, which involves removing the outer insulation of the cable using specialized tools. Depending on customer preferences, we also print the cables.

We look forward to receiving your inquiry.

Do you have any questions about cable assembly or would you like to have an informal exchange with us? We are also your point of contact if you are planning a comprehensive project. Let’s talk about your inquiry, as we provide solutions that combine concept, development, and production under one roof.

Feel free to get in touch with us.

You can also reach me directly by phone: +49 40 285 38-8282

Yours sincerely, Patrick Neikes